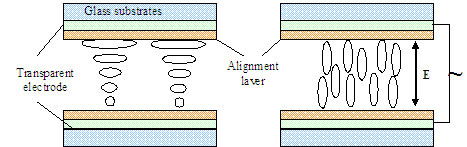

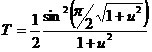

Polarization can be rotated eefectively and achromatically with Liquid Crystal twisted nematic Polarization rotator (TN cell). These TN cells are very useful when one wants to rotate the orientation of a linear Polarization by a fixed amount of typically 45° or 90°. When light is crossing LC twisted nematic cell its Polarization follows the rotation of the molecules (see figure below). The screen of any laptop computer is based on the same effect.

In optical systems, the Polarization is often rotated by quartz retardation plates (l/2 or l/4 plates). Quartz plate shows high quality and good transmission performances especially in the UV region. However, such plates present also some disadvantages: they are expensive, function only for a narrow spectral bandwidth and have a small incidence angle acceptance (field of view less than 2°). The liquid crystal nematic cells have therefore a large acceptance angle, function over a very large spectral range from VIS to NIR (if they are thick enough) and are less expensive. Optionally, by applying a voltage on the TN cell, the Polarization rotation can be "switched off". Also, when placing a 90° twisted cell between crossed polarizers, it can be used as a shutter.

- l/2 plate for a very broadband range of wavelengths

- Optionally rotation effect can be electrically switched off

- In combination with two crossed polarizers it can be used as an optical shutter

- Compatible with pulsed lasers like fs lasers.

| Polarization Rotators Type | Specificities | Applications | Price |

| Industrial grade |

|

|

** |

| Scientific grade |

|

|

*** |

| Custom |

|

|

* / **** |

For more information, please download the product description PDF file in the tabs below or contact ARCoptix: info@arcoptix.com